A glass batching system is a sophisticated process employed in the glass manufacturing industry to precisely mix raw materials in order to create high-quality glass products.

This system is integral to the production of various glass items, including bottles, windows, and glassware. By accurately measuring and blending the right proportions of materials, the glass batching system ensures consistent product quality, optimal chemical composition, and enhanced production efficiency.

In the glass manufacturing process, various materials such as silica sand, soda ash, limestone, and other additives are combined to create the desired glass composition. The glass batching system ensures that these materials are accurately measured and mixed according to predetermined recipes. This is crucial to achieving the required properties of the glass, such as transparency, strength, and thermal resistance.

The glass batching system involves intricate machinery and automation technology to control the dosing of materials. Sophisticated sensors and precision scales are used to monitor and regulate the material flow. These systems can be programmed to adjust the mixing ratios based on factors like product specifications or changing raw material qualities, further ensuring product consistency.

The system’s role goes beyond mere material blending; it also plays a significant role in waste reduction. Precise batching reduces material waste by minimizing deviations from the intended compositions and preventing the need for rework due to faulty batches. This, in turn, has a positive impact on production costs and resource management.

Overall, the glass batching system is a critical component of modern glass manufacturing. By providing accurate material measurements and controlled mixing, it lays the foundation for high-quality glass products that meet the stringent demands of various industries.

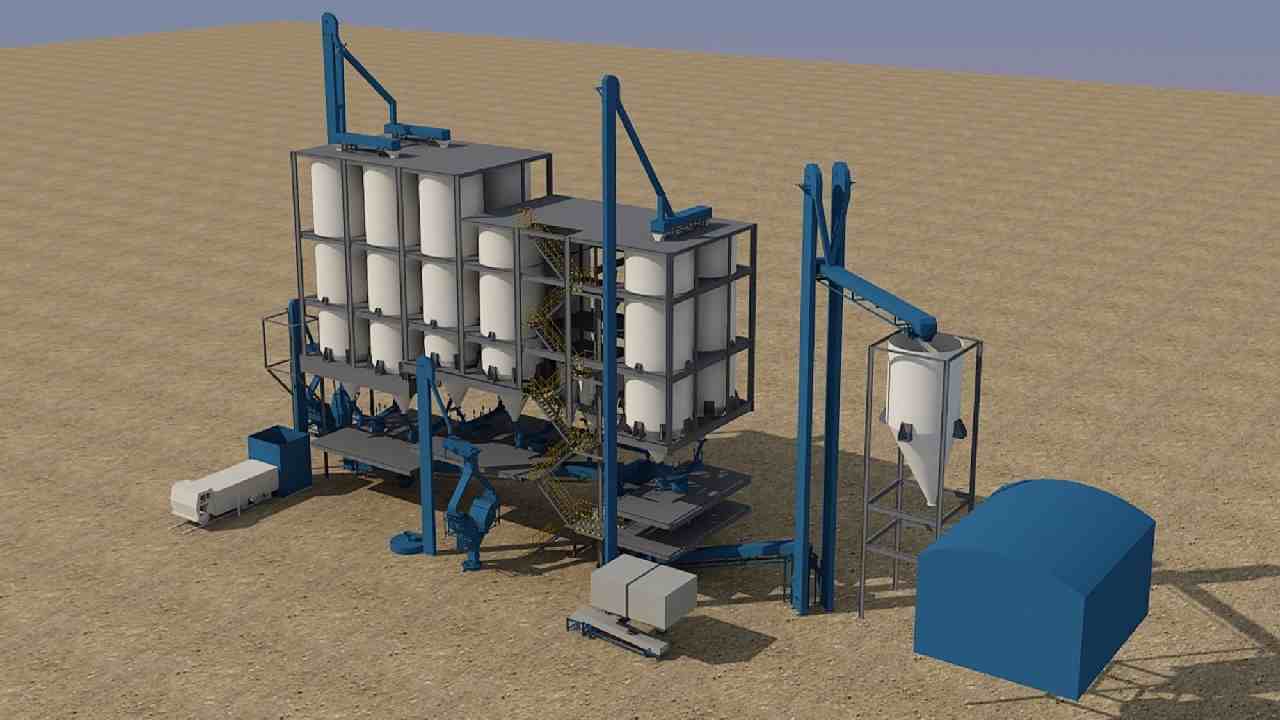

We are competent enough to take up the Batch House Automation as a Turn-Key job right from Engineering, Design, Supply, and commissioning of the Silos, Weighing Hopper, PLC Based Batch Weigher, Material Handling System, and conveying the same to the furnace.