Weight-volume dimensioning is a critical process used in various industries to accurately measure the weight, volume, and dimensions of objects or packages.

This method plays a crucial role in sectors such as logistics, shipping, e-commerce, and warehousing. By combining weight and volume data, companies can optimize space utilization, calculate shipping costs, and ensure accurate billing for their services.

In the logistics and shipping industry, weight-volume dimensioning helps determine the most efficient way to stack and load packages in vehicles, containers, or pallets. By considering both weight and volume, companies can maximize their load capacity while adhering to weight limits. This process streamlines transportation, reduces fuel consumption, and minimizes the environmental impact.

Weight-volume dimensioning also benefits e-commerce businesses that ship various-sized products. By accurately capturing the dimensions and weight of items, companies can calculate precise shipping fees and provide customers with accurate delivery estimates. This enhances customer satisfaction and transparency throughout the purchasing process.

Warehousing operations utilize weight-volume dimensioning to optimize storage space. By understanding the dimensions and weight of incoming goods, warehouse managers can allocate storage efficiently, reducing wastage of space and ensuring proper organization. Additionally, this data aids in inventory management, helping companies avoid overstocking or stockouts.

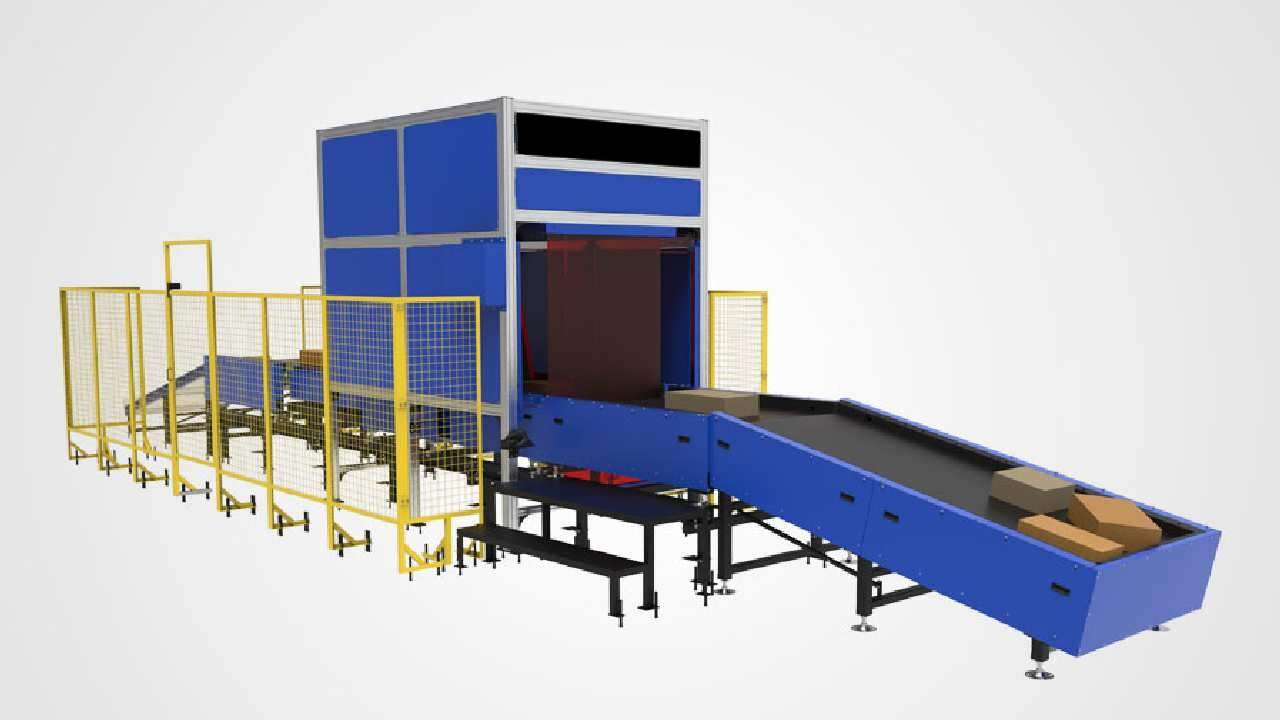

Modern weight-volume dimensioning systems utilize advanced technology, such as dimensioning scanners and load cells, to automate the data collection process. These systems offer accurate measurements, minimize human error, and integrate with warehouse management systems for seamless data sharing. Overall, weight-volume dimensioning is a valuable tool that contributes to efficient logistics, cost optimization, and improved customer experiences.